charpy notched impact strength test|charpy impact test specimen size : supermarket This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test . Escolas de SP programam ‘Dia D’ de mobilização contra a d.

{plog:ftitle_list}

Resultado da Benzoderm ® é um medicamento à base de benzoato de benzila, utilizado no tratamento dos piolhos, lêndeas e da sarna. O conteúdo desta bula foi .

The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .

This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test .

The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the .A Charpy Impact Test involves striking a notched metal sample with a swinging pendulum. The amount of energy absorbed by the sample during fracture is then measured. This provides us with invaluable data about the material’s . Analysis of Charpy impact strength as a function of specimen thickness and curvature. •. Linear relationships between unnotched Charpy impact strength and curvature. .

charpy v notch test procedure

ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the .

It signifies toughness or impact strength of a material. This energy absorption is related to the brittleness of the material. Results of impact tests are expressed in terms of either: . Notched and Unnotched Charpy Test; b) Notched and .Izod impact tester in Blists Hill Victorian Town. The Izod impact strength test is an ASTM standard method of determining the impact resistance of materials. A pivoting arm is raised to a specific height (constant potential energy) and then .

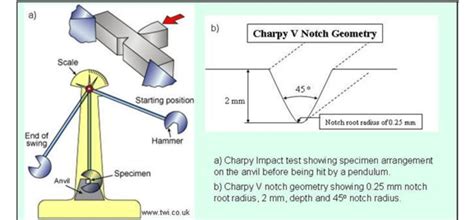

Charpy Impact Test Specimen Dimensions. A Charpy test specimen, which is placed horizontally into the machine, is typically a 55 x 10 x 10mm (2.165" x 0.394" x 0.394") bar with a notch machined into one of the faces. Charpy Impact Test. The Charpy test is less commonly used than the IZOD test and results in a measurement of absorbed Charpy V impact energy, in Joules. . Stress concentration is a major factor in material strength. A sharp-tipped notch will promote fracture by focusing the stress at a point, so notch radius is critically important in .

charpy v notch sample size

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .

The Charpy-V test for characterising notch toughness is described. The qualitative nature of the test, outline procedures and test analysis are described. . The next article in this series will look at the testing of welds, how the impact strength can be affected by composition and microstructure and some of its limitations and disadvantages. What Is the Charpy Impact Test? The Charpy impact test, sometimes called a V-notch test, is a comparative-style test used to define a material’s impact strength by determining how much energy is required to fracture a pre-prepared and standardized sample with a V-notch machined into it. See Figure 1 below: Another very important factor, which influences the toughness, are notches as well as the shape of the notch [12, 13, 14].Cho et al. [15] and Allen et al. [16] investigated the impact strength with a Charpy impact test and found a drastic increase of impact strength with an increasing notch radius for PC.The addition of rubber particles to PC led to a lower increase in . Charpy testing is a method for determining the relative impact strength of metals. It is also known as the Charpy V notch test. This testing method was developed in the 1940s by S.B. Russell and G. Charpy.

charpy impact test temperature requirements

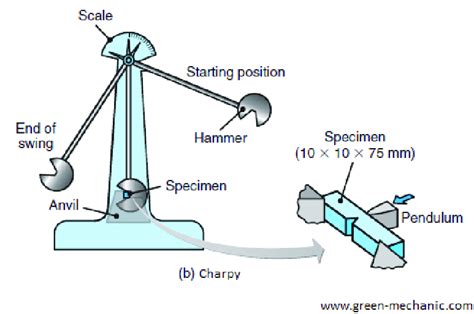

The value of energy absorbed is read directly from a dial on the machine. A typical impact testing machine is shown in Figure. 1. Figure 1. Schematic of a Typical Charpy Impact Testing Machine. In carrying out a test, the specimen is loaded into the anvil with a pair of special tongs that facilitate location of the specimen in the machine. Charpy impact testing, or V-notch testing, is an evaluation of a material’s strength and performance under impact conditions. It involves a pendulum with a pointed hammer on the end swinging and hitting a machined piece of metal cooled to the required temperature to measure the amount of fracture at that temperature.

Four types of impact testing are described in detail below, encompassing the pendulum, drop-weight, and dynamic tear methods: 1. Charpy. The Charpy impact test, also known as the V-notch test, is a type of impact test where a weighted pendulum hammer is released from a specified height and strikes the part. A Charpy impact testing apparatus, a .The Charpy test is a pendulum-based test introduced by Georges Charpy and S. B. Russell. The test was valuable in understanding the material fracture in ships during world war II. The Charpy test consists of a pendulum and a hammer of known mass attached to it. The pendulum swings and hits the notched specimen to observe the energy transfer.

This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D .

Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test. 5.3 For this test method, the energy lost by the pendulum during the breakage of the specimen is the sum of the energies required to initiate fracture of the specimen; to propagate the fracture across the specimen; to throw the free ends of the broken specimen (toss energy); to bend the specimen; to produce vibration in the pendulum arm; to produce vibration or . Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . Factors Affecting Charpy Impact Energy. Yield Strength and Ductility. Notches. Temperature and Strain Rate. . A 5mm deep notch with 1mm .Both methods characterize the impact strength of a material in very similar ways so that the results largely correlate. The Izod test method, in which the specimen is positioned vertically, is normally used in ASTM standards.; The Charpy impact test, which uses a three-point bending arrangement, is the preferred method in ISO standards.; Both methods are used to measure .

Impact Resistance While various methods are available to test for impact strength, the Charpy method of determining impact resistance of notched specimens of plastics (ASTM D6110-10) will be used for this experiment. The impact frame will record the net energy lost by the hammer through impacting and breaking the sample.Scope- This standard specifies the Charpy impact ( V-notch ) method for determining impact strength of the metallic material. 2. Principle - This test consists in breaking by one blow from a swinging pendulum, under conditions defined hereafter, a test piece V-notched in the middle and resting on two supports.CHARPY IMPACT TEST ISO 179 Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. The values recorded can be used for qualityTesting machines for determination of the impact strength of plastics and metals . For a Charpy test, a notched specimen is centered on the supports horizontally with the notch facing away from the pendulum. The pendulum is released to strike and fracture the specimen. Depending on the objective, application and material of the test being .

charpy impact test specimen size

The Charpy impact test is a widely known test famous for its accuracy in measuring metallic and plastic materials. SB Russell and George Charpy introduced this in the 20th century to measure the strength of the material. . Every material must have a notch for focused energy transfer and better testing of the metal’s strength. The notch does .The impact properties include the notched impact strength, as determined with a V-shaped notch, and the un-notched impact strength. (Fig. 5.36) In determining the un-notched impact strength, the entire test piece receives the impact energy caused by the hammer striking, whereas in determining the notched impact strength, breakage is promoted by .

The test result is typically the average of 5 specimens. ISO impact strength is expressed in kJ/m2. Impact strength is calculated by dividing impact energy in J by the area under the notch. The test result is typically the average of 10 specimens. The higher the resulting numbers the tougher the material.

IZOD test is vertical while Charpy tests are horizontal but both measure impact resistance. The main difference lies within a notch sample orientation during testing where in an Izod notched bar impact test, the specimen stands vertically with its notch facing towards the pendulum whereas, during charpy v-notch impact test ,the samples are placed horizontally .

charpy impact test sample dimensions

charpy impact test sample

WEB1 de mar. de 2023 · Está com problemas com TP FINTECH SOLUTIONS? Reclamar. Todas as reclamações para TP FINTECH SOLUTIONS. Exibindo 10 de 229 .

charpy notched impact strength test|charpy impact test specimen size